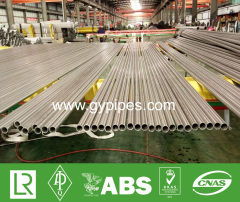

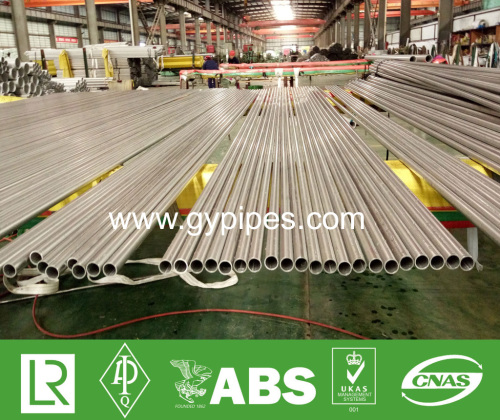

STAINLESS STEELS FOR FOOD-GRADE APPLICATIONS

The Stainless Steel Schedule 10 Pipe of choice in the food services industry is the austenitic 300 series. The stainless used for good pots (like Vollrath) is usually 304. Less expensive pots are often made of 303 alloy stainless, which is less weldable and is quickly attacked by chlorinated cleaners. Other stainless kitchen equipment, like utensils, are typically ferritic stainless, which has less chromium and nickel and is less acid-neutral.

The Stainless Steel Schedule 10 Pipe was originally developed for use in cryogenics. These steels also perform well at elevated temperatures and are used extensively for steam pipes and exhaust systems. It is their resistance to elevated temperature, oxidation, and corrosion that makes alloys 304 and 316 the choice for food preparation equipment, including steam-heated boilers and storage tanks. But every silver lining has its cloud, and when it comes to joining stainless steel, that cloud is heat. The metallurgy that makes these alloys corrosion resistant and strong also makes welding more difficult than is the case with ordinary steel.

METALLURGY BASICS

What makes a steel stainless? The addition of chromium and nickel to the iron creates a significant percentage of chromium and nickel atoms at the surface. These atoms form tenacious oxides that seal the surface and prevent oxidation of the iron. The process known as passivation for stainless steel (see the article by Micah Millspaw in a previous issue of BrewingTechniques [1]), is a common means of improving this protective oxide layer through the use of oxidizing acids. Anodizing aluminum alloys is a similar method in that a solid aluminum oxide barrier is created to prevent further corrosion. Like stainless steel, anodized (black) aluminum cookware (Magnalite, Calphalon) is acid neutral and resistant to acidic food because of this heavy oxide layer. Plain (bright) aluminum cookware lacks the degree of surface oxides necessary to prevent reaction with corrosive media.

Stainless steel's Achilles heel: All metals are crystalline materials that have specific crystal structures that are dependent on temperature. These structures are referred to as phases and are given names such as austenite and ferrite. A block of metal is very similar to a block of salt. A block of salt is really a bunch of grains of salt all fused together. These grains are oriented every which way, and the interface to the next grain of salt is called the grain boundary. As you would expect, the grain boundary is weaker than the grain itself. The crystalline structure of metals is exactly the same in this respect. (By the way, if you would like to see a metallic grain structure, go look at an aluminum street-light pole. That mosaic you see is the grain structure.) Because the grain boundaries within a metal are the weakest sites, heat and corrosion usually affect these areas first.

The corrosion resistance of stainless steel depends on the chromium. Austenitic stainless is a supersaturated solution of chromium and nickel in iron. It is actually a very high temperature phase that has been quenched (quick-cooled) to preserve the distribution of elements.

Austenitic stainless does not like middling-high heat. It performs well up to 600 °F (315 °C), but higher temperatures in the range of 800-1600 °F (425-870 °C) cause atom diffusion and change the metal's properties. Such high temperatures allow the chromium to diffuse away from the grain boundaries to form chromium carbides, its preferred crystalline structure at that temperature range. If exposed to these high temperatures and chromium diffusion occurs, the metal becomes sensitized and prone to cracking. The diffusion of chromium away from the grain boundaries results in non-stainless grain boundaries surrounded by stainless steel. This situation soon leads to localized corrosion and rapid cracking of the grain boundaries. To correct this, the metal must be heated to at least 1900 °F (1040 °C) for a period of time in an inert gas atmosphere and then quenched to retain the austenite crystal structure. Unfortunately, doing this heat treatment to a welded keg would result in considerable warping and distortion. It is better to get another keg and start over.

Welding is a local melting-freezing process that creates high temperature gradients in the metal around the weld. This heat affected zone (HAZ) is the region where unwanted atom diffusion can take place if it is hot enough, long enough. Time/temperature curves describe this phenomenon, and the curve for alloy 304 is shown in Figure 1. The figure shows that for type 304 stainless (nominal carbon content of 0.08%), 5 min at 600 °C (1110 °F) or higher will cause chromium diffusion that will later cause cracking in service. Type 304L stainless - "L" denoting less carbon (nominal 0.03%) - is more weldable and can spend about 6 hours at 600 °C before becoming sensitized. Most kegs (in North America) are made from 304L to facilitate welded construction.

Caution must be taken when heating stainless steel equipment. I know of one home brewer whose cut-off keg boiler began cracking at the bottom. The cracks appeared at the flame line where the flame of the cajun cooker-style propane heater met the keg. This shows that he was running the flame too hot and that, over time, chromium atom diffusion was taking place.

Diffusion is cumulative.

Once this type of cracking occurs, there is no economical way to correct it.