1. Typical Surface treatment for Steel building ( made of steel structure frame ) :

Surface Treatment |

Hot dip galvanize |

Standard : JIS , DIN , ASTM B695 - 2000 |

Hot dip galvanizing hole cutting good looking on surface |

Galvanizing process : Steel structural components → Degreasing → Rinsing→ Pickling → Rinsing → Fluxing → Galvanizing → Quenching → (Passivation) → Inspecting → Finished Product |

Paint |

1 . Primer paint one coat 20 - 30 um |

2 . Middle paint two coat 40 - 60 um |

3 . Finish paint one coat 20 - 30 um Paint type : 1 . red primer 2 . zinc primer 3 . Alkyd primer |

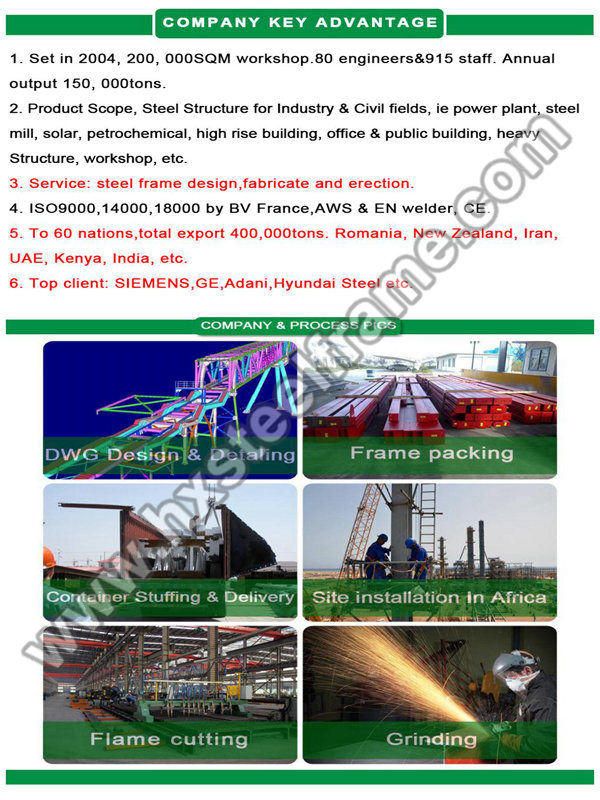

2. Our company advantage:

1) Enough capacity

Our factory is occupies an area of 200000 m2, We have 1020 workers. 15, 000tons steel structure per month, So we have enough capacity for your demand on Steel building ( made of steel structure frame ) .

2) Advanced technology

There are 300 sets advanced technology equipment. The CNC cutting machines which are imported from USA to make sure the precise size be cut.

3) customized design

We have 62 senior design engineers, 25 shop dwg detailing engineers. our technology department can make a optimal design just for you review according your requirements and local weather condition.

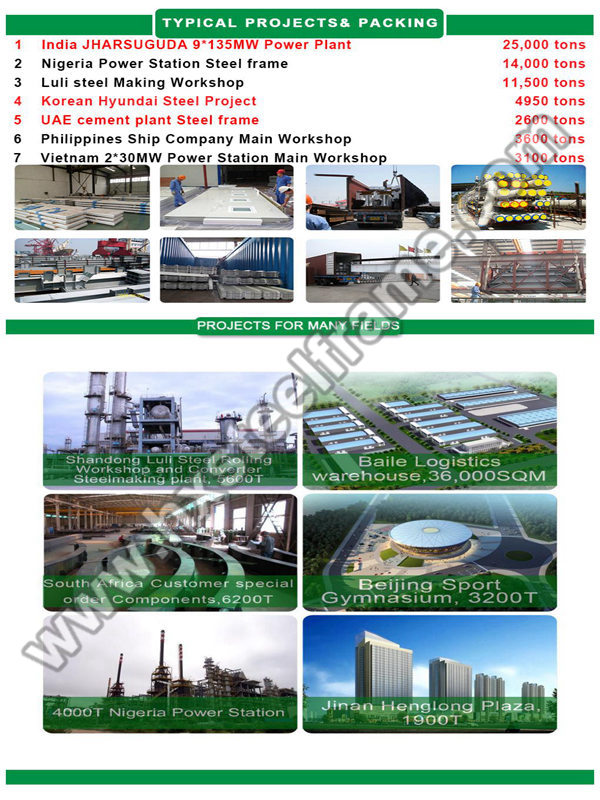

3. Overseas projects we undertook in the last few years:

Industrial Warehouse(13000 m2)― Argentina

Warehouse(14000m2) , Republic of Uzbekistan

Workshop(12000m2) , Canada

Warehouse(3600m2) , Romania

Vegetable Market(2500m2) , Mauritius

Pig shed(3500m2) , USA

Chicken shed(2800m2) , Australia

Aircraft Hangar(1300m2) , Australia

Warehouse(900m2) , Mongolia

Prefabricated house(70m2) , 800 sets , Angola

Container house(20' ) , 60 sets , South Africa

4. Our quality system and welder certificates for Steel building ( made of steel structure frame ) :

From first day of our establishment, we concentrate on making the produce as per highest international quality standard.

Based on this concept, we continuously improve our quality system, and got international certificate as below:

Got AISC qualification and CWI welding inspection certificate as per American standard, have 163 American AWS welder.

Got EN1090 qualification, TWI welding inspection certificate and IWE welding engineer as per European standard, have 54 European standard welder.

In China, there are very few companies could own all such international certificates like us.

5. Our seaworthy packing system for Steel building ( made of steel structure frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How can I install these Steel building ( made of steel structure frame ) together as a building after cargo arrived ?

Normally, most clients choose to install the steel building structure frame themselves or ask local technical engineer for further instruction.

If local technical support is not available or cost too much, we could also provide technical support engineer cross over-seas for installation guide even with our installation engineering team.

2) How to maintain my Steel building ( made of steel structure frame ) years of using ?

Steel building ( made of steel structure frame ) are built for long-time, reliable, steady usage purpose, the maintenance process is easy to operate and complete, most our product can live 10-15 years with minimal maintenance work like gel filled and paint spray. We will keep tracking the usage performance of our products and provide maintenance instruction for our clients.