mechanical shaft seals JOHN CRANE 680 metal bellow for high temperature use in oil pumps and chemical pumps that we sell is of high precision, good performance and competitive price

Welded metal bellow seals

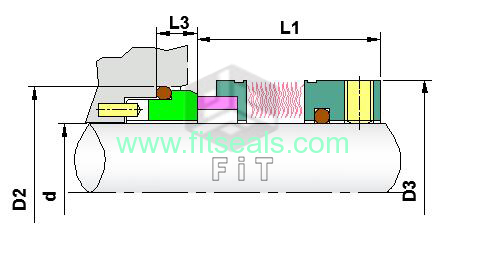

Specifications

Bellow seal designed for media with high viscidity such as crude oil and asphaltum

Structure

1)Single/Cartridge

2)Single/Double-ply bellow seal

3)Secondary seal-O ring

4)Self-flushing function

5)45°inner diameter of bellow

Material

1)Mating rings: carbon×sic/wc

2)Metal bellows: 316L, AM350, Inconel 718

Application

High temperature & high viscidity working condition, in the field of petrochemical, refinery, pharmacy industries.

| /Size | D3 | L1 | /Size | D3 | L1 | |

| 0.750 | 1.312 | 1.250 | 18 | 32.00 | 27.70 | |

| 0.875 | 1.437 | 1.250 | 20 | 33.30 | 27.70 | |

| 0.937 | 1.500 | 1.250 | 22 | 36.00 | 27.70 | |

| 1.000 | 1.562 | 1.250 | 24 | 38.10 | 30.20 | |

| 1.125 | 1.687 | 1.250 | 25 | 39.00 | 30.20 | |

| 1.250 | 1.812 | 1.312 | 28 | 42.00 | 32.70 | |

| 1.375 | 1.937 | 1.437 | 30 | 44.00 | 32.70 | |

| 1.500 | 2.063 | 1.437 | 32 | 46.00 | 32.70 | |

| 1.625 | 2.187 | 1.437 | 33 | 47.00 | 32.70 | |

| 1.750 | 2.312 | 1.437 | 35 | 49.20 | 32.70 | |

| 1.875 | 2.437 | 1.500 | 38 | 52.40 | 34.20 | |

| 2.000 | 2.562 | 1.500 | 40 | 55.60 | 34.20 | |

| 2.125 | 2.687 | 1.500 | 43 | 58.70 | 34.20 | |

| 2.250 | 2.812 | 1.562 | 45 | 58.70 | 34.20 | |

| 2.375 | 2.937 | 1.562 | 48 | 61.90 | 34.20 | |

| 2.500 | 3.187 | 1.562 | 50 | 65.10 | 34.70 | |

| 2.625 | 3.312 | 1.625 | 53 | 68.30 | 34.70 | |

| 2.750 | 3.437 | 1.625 | 55 | 71.00 | 34.70 | |

| 2.875 | 3.625 | 1.687 | 60 | 74.60 | 39.70 | |

| 3.000 | 3.750 | 1.687 | 65 | 84.10 | 39.70 | |

| 3.125 | 3.875 | 1.750 | 70 | 87.30 | 45.20 | |

| 3.250 | 4.000 | 1.750 | 75 | 95.30 | 45.20 | |

| 3.375 | 4.125 | 1.750 | 80 | 98.40 | 44.70 | |

| 3.500 | 4.250 | 1.875 | 85 | 104.80 | 44.70 | |

| 3.625 | 4.375 | 1.875 | 90 | 108.00 | 49.70 | |

| 3.750 | 4.500 | 1.875 | 95 | 114.30 | 49.70 | |

| 3.880 | 4.625 | 1.875 | ||||

| 4.000 | 4.750 | 1.875 |

Metal bellows seals have many advantages over common pusher seals. The obvious advantages include:

- No dynamic o-ring eliminating the possiblity of hang-ups or shaft wear.

- Hydraulically balanced metal bellows allow the seal to handle more pressure without heat build up.

- Self Cleaning. Centrifugal force throws solids away from the seal face - Trim design allow fit into tight seal boxes

- Even face loading

- No Springs to clog

Most often metal bellows seals are thought of as High Temperature seals. But metal bellows seals are often effective in a wide range of other seal applications. The most common of these is chemical, general water pump applications. For many years an inexpensive form of metal bellows seals have been used very successfully in the waste water / sewage industry and in the agricultural fields pumping irrigation water. These seals were generally made of a formed bellows rather than a welded bellows. Welded bellows seals are much stronger and have superior flex and recovery characteristics which are more ideal to holding seal faces together but cost more to manufacture. Welded metal bellows seals are less prone to metal fatigue .

Because metal bellows seals only require one o-ring, and because that o-ring can be made with PTFE, metal bellows seals are and excellent solution on chemical applications where Kalrez, Chemrez,Viton, FKM, Buna, Aflas or EPDM are not compatible. Unlike an Type 9 seal the o-ring will not cause wear because it is not dynamic. Installation with a PTFE o-ring must be done with more attention paid to surface of the shaft condition, however PTFE encapsolated o-rings are also available in most sizes to aid in sealing irregular surfacing.

The Type 680 is the ideal seal for general-purpose applications. Its Alloy 20 bellows provide corrosion resistance in a broad range of services. Its cost-effective design, combined with a reliable performance history, has made the Type 680 the standard for many applications found in the chemical, water and wastewater, pulp and paper, and utility industries